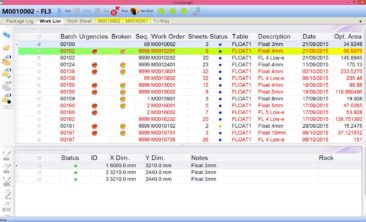

Line Manager is a Cutting Control Station typically installed near the cutting table Numeric Control. Specifically designed to manage complete cutting lines with Crane Loaders, Automatic Break-out and Display Systems, Offcut Storage and Sorting Systems.

Line Manager “offers” coordination, communication, casting, centralized management of application concerning the cutting, but also the applications that perform the working immediately following or preceding that of glass cutting, to create a single complex and thus realizing a more efficient and costeffective organization of the production cycle. Through its interface organized in TAB with several monitors management and the communication protocols with the HMI applications of the cutting table (including glass loader HMI Interface) it’s possible to coordinate and manage all activities related to the glass cutting directly from the Line Manager interface

Functionality

- Centralized Supervisor of all Cutting Line Functions

- Real-Time Control of Crane Loader, CNC Cutting Table

- Offcut Storage and Sorting Systems

- Management of Job Lists according to Production Scheduling coming from the office Opty-Way Enterprise ERP System

- Stop or pause the cutting sequence and may switch to another Work Order

- Plane by Plate CNC code for Cutting Machine

- Online Offcuts Management

- Scanner Interface for defect recognition and visualization

- Real-Time Glass Stock Synchronization Between Crane Loader and Opty-Way Enterprise

- Traceability and Cutting Time Recording

- Production Cutting and Wastage Statistics